EPP Auto Parts

EPP is polypropylene foam material, an excellent high crystalline polymer & gas composite material, with light specific gravity, good elasticity, anti-vibration & crush resistance, high deformation recovery rate, oil resistance and heat insulation characteristics, which is really eco-friendly, non-toxic, odorless and recyclable.

With its unique and superior performance, it has become the fastest growing environmental protection new anti-compression buffer insulation material. Due to its light specific gravity, good elasticity, anti-vibration & crush resistance and recyclable, EPP foam material has been rapidly applied in the field of automobile manufacturing since it had been developed in the 1990s, becoming a new favorite of energy absorption and shock absorption materials.

1. Product characteristic

Excellent heat resistance, maximum at 130℃, at -40℃ it still has excellent buffering performance which usable temperature is much higher than EPS and EPE. Good dimensional stability, tiny heat shrinkage, stable dimension, long us life, environmentally friendly and harmless, and recyclable many times.

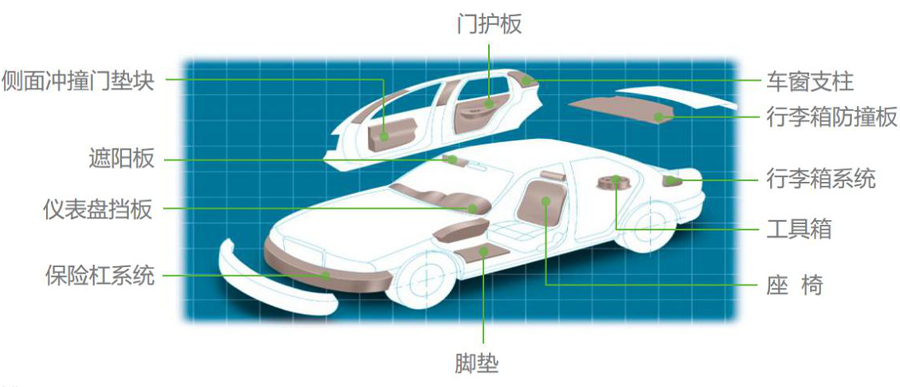

2.Use for Auto Industry

EPP beads can be molded into EPP products of different shapes by the EPP molding machine.EPP is widely used in auto parts, such as bumper core material, anti-collision block, ceiling lining, door filling, head pillow, sunshade, etc., which can save oil consumption and improve the safety of passengers.

Earthmother EPP auto parts partners currently include Toyota, Hyundai, Kia and other auto manufacturing companies which offer customized product design according to their needs.

3.Product Feature